Before my last ski trip I wanted a helmet-cam. I bought an Oregon Scientific ATC3K digital video camera, but the mount was just too bulky for a helmet rig. It’s great for mounting on a kayak or mountain bike, but totally unsuitable for a real helmet mount. (It’s just too big.) Obviously, it was time for a bit of modding.

Parts & Tools:

- Soldering iron

- De-soldering iron

- Dremel (rotary cutting tool)

- Small screw drivers

- Oregon Scientific ATC3K Video Camera

- Ski goggles

- AA battery box

- IDE hard drive cable

- Small plastic case

Take the camera apart

Start by disassemble the camera. Unscrew the back cover and

pry off the rubber from the lens end. Remove all of the exposed screws

and pop open the battery cover. Unscrew the rear cap and remove the

batteries.

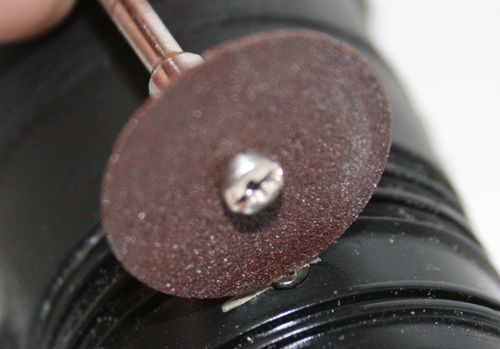

You’ll have to cut slots into the two security screws in

order to use a normal screwdriver on them.

If you’re lucky, the battery tray and camera will slide out of the

body of the camera now. If it’s too stubborn, you may have to cut the

body of the camera in half to help things along.

De-solder the camera board

The camera is mounted to the main board by ten pins on either side of the main board. Grab your soldering iron and add more solder so that on each side a large bead of solder covers all ten pins. Use your soldering iron to heat the entire bead. Once it’s melted, you can partially pry the camera board from the main board. Repeat the process on each side until you can remove the camera board entirely. Be patient and give the camera board time to cool down in between heating sessions. Once the board is free, de-solder the entire connector and remove any excess solder from both boards.

Add the ribbon cable to the camera board

Grab an IDE hard drive cable and cut the longest piece out of it that you can. Now peel off a piece of cable that has 20 wires in it – preferably with the red mark to make wiring it up easier later on. Strip about 2mm of wire at the ends and cut them flat.

Now solder the leads to the camera board, where the old connector was.

Repeat the process to complete the remote cabled camera board.

Now we’ve got a nice, easily mountable camera. This should work for various different build ideas: helmet mounts, custom enclosures, embedded motorcycle cams…

Mount the camera and microphone

Locate the camera on the lens and drill a hole through the lens of your goggles. Blow out the dust with a can of compressed air if you end up with debris inside the double lens. Position the camera and use hot glue to permanently mount it to the inside of the goggles.

Now route the camera ribbon cable along the edge of the goggles and out through the strap mount.

On my goggles, it was easy to pull the ribbon cable through the hole for the strap.

Mount the Microphone

Re-use the microphone from the ATC3K and add some new wires. The soft wire from some old headphones will help isolate the microphone from vibration noise. Pull the end of the audio cable out the side of the goggles where the

strap attaches. If needed, mount the microphone on the bottom of the goggles with a small amount of glue.

Wire the main board

Trim the ribbon cable to length and solder it to the main pc board

where the camera originally mounted. Use the red marked cable to make

sure you connect the correct pins. Attach the microphone wires and a pair of wires

that are long enough to reach the far side of the goggle strap.

Running power

Pull the power leads through the goggles so that they will be out of

the way. Run them out the far side of the goggles and connect them to

a replacement AA battery box.

Originally I wanted to use AAAs, but I found that AA batteries balanced the goggles better.

Enclose the main board

We want to protect the main board with something that’s removable and

waterproof. I made a custom enclosure on my computer controlled mill,

but a simple plastic bag with tape will suffice in a pinch. In the final build, I mounted the control buttons (seen behind the red acrylic) on top of the acrylic with some hot glue.

The body was milled from two pieces of polyethylene cutting board.

The cover was milled from some acrylic I had left over from some laser cutter projects.

I thought about some complicated mounting tricks to attache the boxes to the straps, but found that electrical tape worked great. Keep in mind that the cold will drop the voltage on your average alkaline batteries - get some of the lithium AAs or the camera will keep shutting down.

(Source Biobug.org)

No comments:

Post a Comment